Petroleum laboratories are different from general chemical laboratories. Operators have been exposed to a large number of petroleum samples and chemical reagents for a long time, most of which are toxic, flammable, and explosive. Any improper operation may cause fire, explosion, and poisoning. Therefore, the standardized management of petroleum laboratory safety must be combined with the characteristics of petroleum laboratories to avoid accidents.

★Characteristics of oil laboratory★

1 Oil inspection is highly professional

Different from the chemical laboratory, the oil laboratory covers two parts: physical and chemical performance inspection and oil condition monitoring. Therefore, more flammable and explosive gases and reagents are used, and the hidden safety hazards are relatively complicated.

2 There are many analysis items

At present, my country's oil laboratory management includes internal moisture, viscosity, density, water separability, flash point, acid value, pour point, freezing point, pollution degree, elemental analysis and many other technical tests. The instruments used are rich and diverse. , one of which includes two types of moisture determination methods: distillation and trace moisture content.

3 There are many harmful gases

The flash point of oil and water (distillation method) are likely to produce more toxic and harmful gases during the detection process, and the detection items such as pollution are exposed to petroleum ether reagents, which are likely to cause harm to the human body.

Hazardous chemicals and protective measures commonly used in petroleum laboratories

There are three types commonly encountered in petroleum laboratories: compressed and liquefied gases, flammable gases, and corrosive products.

Some gases, such as hydrogen, nitrogen, oxygen, and acetylene, are used in petroleum laboratories for various analyses. Most laboratories use gas cylinders to meet the needs of analysis. There are many unsafe factors in the use of gas cylinders. Only by using gas cylinder safety standards can accidents be prevented.

1 Compression for gas and liquefaction as well as gas

Compressed and liquefied gases are potentially unsafe, flammable and explosive. At present, petroleum laboratories generally use the liquefied petroleum gas cylinders of the open-air flash point tester and the compressed air of the pollution tester.

Protective measures:

The liquefied gas cylinder must be fixed upright, away from heat and fire sources, and not exposed to the sun; when transporting, cover the cylinder head and handle it with care to prevent accidental throwing, knocking, rolling or violent vibration, and avoid explosion caused by impact. When using, the operation rules must be strictly followed, otherwise it may cause an explosion accident. The gas in the gas cylinder cannot be completely used up, and the combustible gas should be kept at 0.2 MPa-0.3 MPa. Gas cylinders should be checked regularly to prevent gas leaks.

2 Flammable liquids

Flammable liquids are highly volatile and can be ignited in the presence of an open flame. Flammable liquids commonly used in petroleum laboratories include ethanol, petroleum ether, solvent gasoline, etc.

Protective measures:

All flammable gases should be stored in a low-temperature ventilated place, and the storage temperature should not be higher than 25°C, away from fire, heat and light sources. It cannot be stored together with oxidants; it is forbidden to use tools that are prone to static sparks to open the bottle cap. When the concentration in the air exceeds the standard, you need to wear a self-priming filter gas mask and special protective glasses during operation; wear latex gloves when touching it with your hands.

3 corrosive products

Corrosion products include hydrochloric acid and sodium hydroxide, which are commonly used in laboratory research through liquid and solid oil products. the

Protective measures:

Hydrochloric acid gas is irritating to eyes, skin and mucous membranes, so it is necessary to complete the operation in a fume hood. If you inhale hydrochloric acid, you can inhale a small amount of alcohol and mixed steam to detoxify. Neutralizers containing sodium hydroxide can cause burns. In case of accidental contact, rinse with copious amounts of water followed by diluted acetic acid. If you get a chemical burn in your eye, rinse it immediately with water from a laundry bottle (don't get water directly in your eye and don't rub it). After washing, if it is an alkali burn, then rinse with 2% boric acid.

★Precautions for using gas cylinders★

(1) Gas cylinders must be stored separately and in different places to contain gas cylinders that may cause combustion or explosion after contact with each other, and must not be stored together or side by side with other flammable or explosive items. When placed, cylinders shall be secured so as to ensure that they cannot be moved or toppled due to natural hazards.

(2) The quality of gas cylinders should usually be placed in a cool, dry, special room away from the main heat source. It is strictly forbidden to use open flames and avoid exposure to the sun. The temperature of different environments should not exceed 35°C. the

(3) When moving cylinders, wear cylinder caps and rubber waist rings to protect the control switch valve, prevent accidental rotation and reduce collisions, and handle cylinders with care to prevent throwing, knocking, and sliding Or violent social shocks, to avoid the information explosion caused by the impact effect. the

(4) When installing the pressure reducing valve, first check whether the pressure reducing valve matches the gas cylinder, and then remove the dust and other dirt in the outlet of the high pressure gas cylinder, the interface of the pressure reducing valve and the pipeline (to prevent blockage). Tighten the screws during installation to prevent leakage.

(5) When opening the gas cylinder, one should stand on the side of the gas cylinder outlet to avoid being injured by the airflow. When in use, turn the switch valve first, and then open the pressure reducer; after completion, close the switch valve first, and then close the pressure relief valve after the residual gas is discharged; Excessive gas flow creates static sparks and explosions.

(6) The gas in the steel cylinder cannot be completely used up, the internal residual pressure should be kept above 0.05 MPA, the combustible gas should be kept at 0.2 MPA ~ 0.3 MPA, and the hydrogen gas should be kept at a relatively high pressure for aerator inspection and sampling needs , to prevent other gases or impurities from mixing and causing accidents.

(7) Gas cylinders that are easy to polymerize, such as acetylene, should be used within the storage period.

(8) When the gas cylinder is on fire, pour cold water on the cylinder and use a large amount of it, or put the cylinder into water to cool it. the

(9) Steel cylinders must be checked regularly. General gas cylinders are inspected every three years. Cylinders storing inert gases are inspected every five years; cylinders storing corrosive gases are inspected every two years.

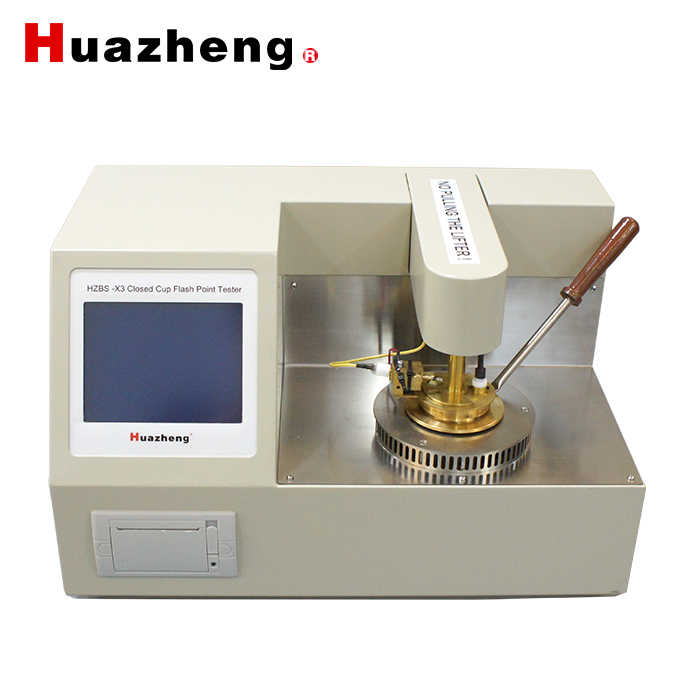

HZBS-X3 Closed Cup Flashpoint Measuring Instrument